Understanding Sulfate Attack

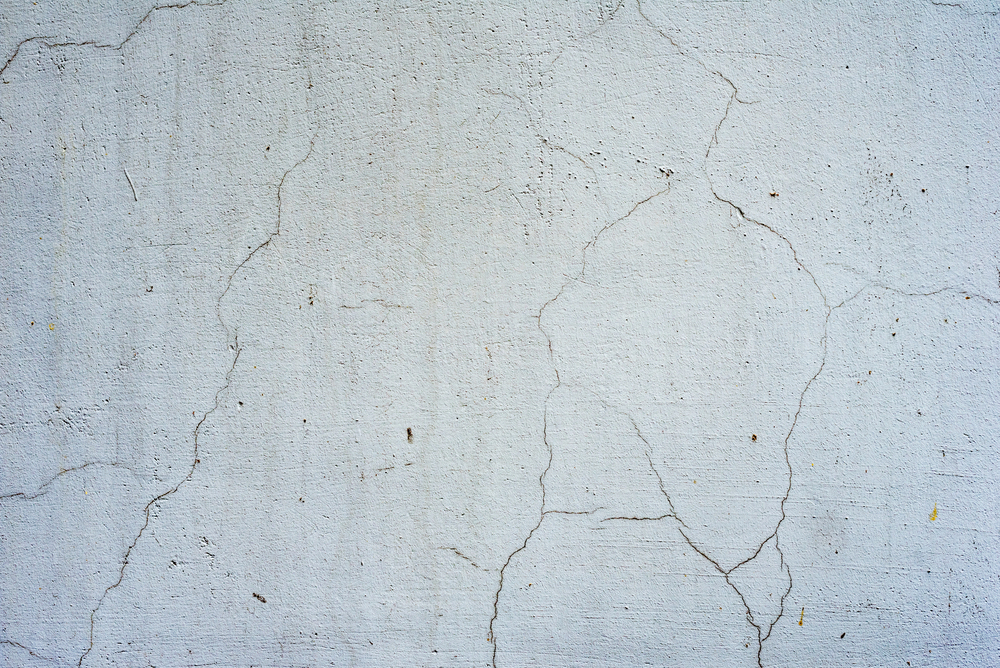

Sulfate attack is a prevalent form of concrete deterioration that occurs when sulfate ions (SO₄²⁻) present in soils, seawater, or industrial effluents infiltrate concrete structures. These ions react with hydration products of portland cement, particularly tricalcium aluminate (C₃A) and calcium hydroxide (Ca(OH)₂), leading to the formation of expansive compounds like ettringite. The resultant expansion induces internal stresses, causing cracking, spalling, and ultimately compromising the structural integrity of concrete.

Several factors influence the severity of sulfate attack:

- Concrete Permeability: Higher permeability facilitates the ingress of sulfate ions.

- Sulfate Concentration: Elevated levels of sulfates in the environment accelerate deterioration.

- C₃A Content in Cement: Higher C₃A levels increase susceptibility to sulfate reactions.

- Calcium Hydroxide Presence: Abundant Ca(OH)₂ provides more material for deleterious reactions.

Slag Cement’s Role in Mitigating Sulfate Attack

Incorporating slag cement into concrete mixtures has proven effective in enhancing resistance to sulfate attack through multiple mechanisms:

1. Reduction of C₃A Content

Slag cement inherently contains minimal to no tricalcium aluminate. When blended with portland cement, it dilutes the overall C₃A content in the mixture. This reduction diminishes the potential for ettringite formation, thereby mitigating the risk of sulfate-induced expansion and cracking.

2. Decreased Permeability

The use of slag cement refines the pore structure of concrete, resulting in a denser matrix with reduced permeability. This densification hinders the penetration of sulfate ions, limiting their interaction with vulnerable hydration products. Consequently, the progression of sulfate attack is significantly slowed.

3. Consumption of Calcium Hydroxide

Slag cement participates in pozzolanic reactions with calcium hydroxide, converting it into additional calcium silicate hydrate (C-S-H). This process not only strengthens the concrete matrix but also reduces the availability of Ca(OH)₂ for harmful sulfate reactions.

For a deeper understanding of how slag cement enhances concrete durability, refer to The Science Behind Slag and Structural Integrity.

Performance in Sulfate-Rich Environments

Research indicates that concrete incorporating slag cement exhibits superior performance in sulfate-laden environments. Studies have demonstrated that slag-blended cements can achieve sulfate resistance comparable to or exceeding that of specially formulated sulfate-resisting portland cements. This makes slag cement an ideal choice for structures exposed to aggressive sulfate conditions, such as: PMC+5ASCE Library+5Knowledge Core Repository+5

- Marine Structures: Piers, docks, and seawalls.

- Underground Foundations: Basements and footings in sulfate-rich soils.

- Wastewater Treatment Plants: Facilities handling sulfate-containing effluents.

- Industrial Floors: Areas exposed to sulfate-bearing chemicals.

For insights into sustainable construction materials, including slag cement, explore Sustainable Construction Materials.

Best Practices for Utilizing Slag Cement

To maximize the benefits of slag cement in mitigating sulfate attack:

- Optimal Replacement Levels: Replace 25% to 65% of portland cement with slag cement, depending on exposure severity.

- Proper Curing: Ensure adequate curing to develop a dense, impermeable concrete matrix.

- Quality Control: Maintain consistent mixing and placement practices to achieve uniformity.

For guidance on mix designs and material selection, refer to Types of Supplementary Cementitious Material Used in Concrete.

Conclusion

Sulfate attack poses a significant threat to the longevity and integrity of concrete structures. By incorporating slag cement into concrete mixtures, engineers and builders can effectively enhance resistance to sulfate-induced deterioration. The combined benefits of reduced C₃A content, decreased permeability, and consumption of calcium hydroxide make slag cement a robust solution for constructing durable, long-lasting structures in sulfate-rich environments.

For more information on how slag cement can improve the performance of your concrete projects, contact Sathi USA.